Advanced power fuses serve as crucial safety devices in electrical systems by interrupting electrical flow during overloads or short circuits, thereby protecting equipment and preventing fire hazards. As technology evolves, so have these fuses, integrating quicker response times and higher current capabilities. This evolution makes them indispensable for modern, high-demand electrical systems.

A study by the National Fire Protection Association (NFPA) highlights that advanced power fuses significantly reduce electrical accidents, showing a marked decrease in incidents related to faulty electrical components. These statistics underscore the critical role these fuses play in enhancing electrical safety across various settings.

Furthermore, advanced power fuses seamlessly integrate with other safety measures, such as circuit breakers and surge protectors, providing a comprehensive safety solution for electrical systems. Their ability to respond promptly to electrical irregularities ensures the maintenance of a safe working environment, making them a key component in both residential and industrial electrical safety strategies.

When it comes to electrical safety, advanced power fuses offer diverse options tailored to specific needs. Current limiting fuses are crucial for protecting downstream equipment. They effectively restrict the flow of current during fault conditions, safeguarding against potential damages. These fuses are particularly efficient in systems where quick disconnection is vital to preventing equipment failures or fire hazards.

On the other hand, time lag fuses, often referred to as slow-blow fuses, are indispensable in applications that experience inrush currents. These fuses allow temporary excess current, which helps accommodate the initial surge without causing immediate failure. This feature is crucial in environments with motors or devices requiring extra start-up current, enhancing both performance and longevity.

Finally, blown fuse detection technologies have revolutionized modern electrical systems by enabling automatic notifications. This technology is vital as it reduces downtime by quickly identifying faults before they escalate. These smart systems ensure safety by promptly alerting maintenance teams, allowing timely intervention and minimizing operational interruptions.

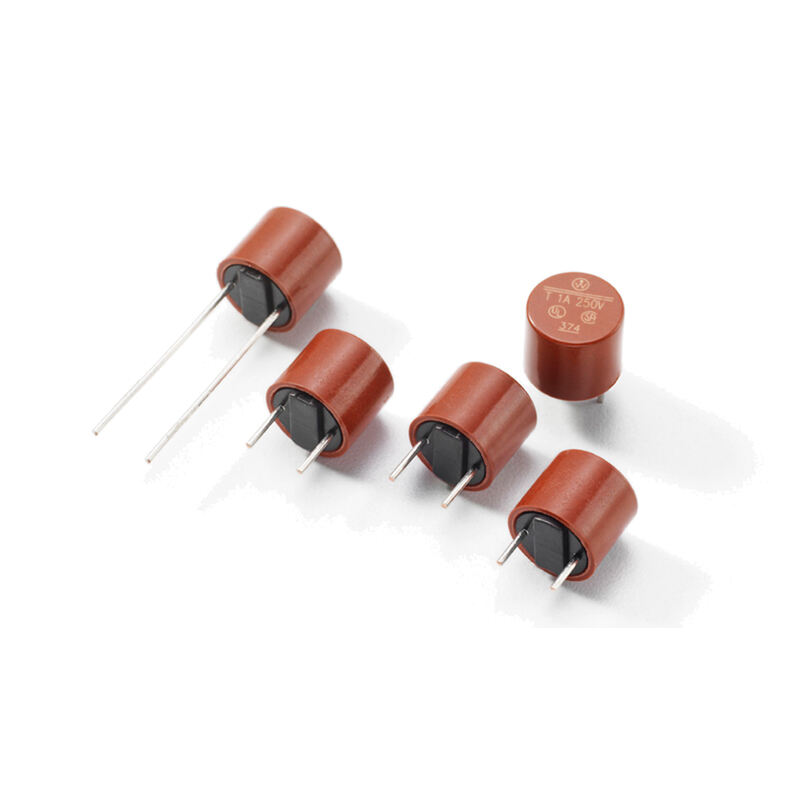

When it comes to compact and reliable solutions, the 374 Series 250V Time Lag Littelfuse Subminiature Fuses stand out. These fuses are specifically engineered for environments where space is limited while ensuring high reliability. The 374 Series offers several features including halogen-free, lead-free, and RoHS compliance, with a high breaking capacity that makes them suitable for a range of applications from consumer electronics to industrial controllers.

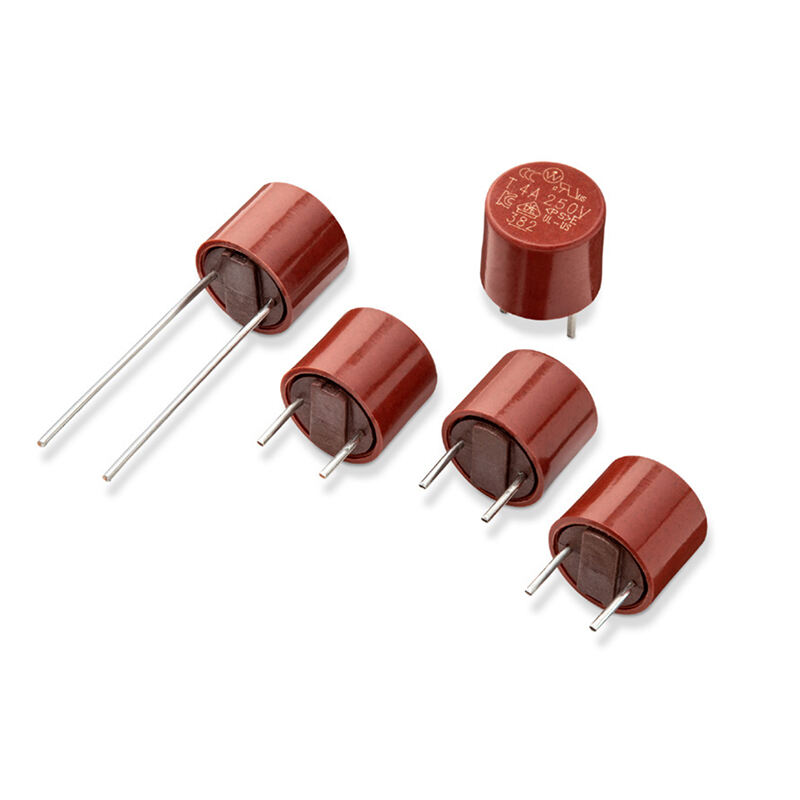

For applications needing robust motor protection and control circuit reliability, the 382 Series 250V Time Lag Littelfuse Subminiature Fuses provide enhanced performance. These fuses prioritize safety with features like a 100A breaking capacity and shock-safe casing while supporting both solderable and plug-in versions. Their international approvals underline their reliability, suitable for applications from power supplies to industrial controllers.

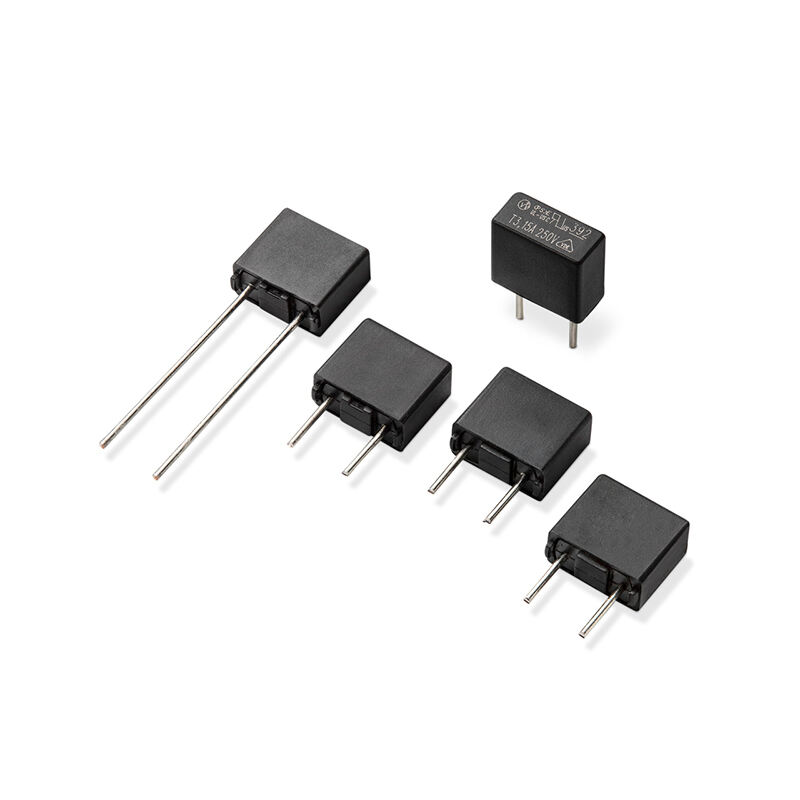

The 392 Series 250V Time Lag Littelfuse Square Subminiature Fuses excel in providing superior thermal performance. Boasting features such as reduced PCB space requirements and a square design, they are ideal for ensuring durable solutions across diverse electrical applications. These fuses meet international standards, reflecting their robustness and effectiveness in environments like consumer electronics and industrial machinery.

Installing advanced power fuses correctly is crucial for maintaining system integrity and ensuring optimal performance. To begin with, always make sure the circuit is de-energized to prevent any electrical hazards during installation. It is important to verify that the correct fuse rating is used, as this will ensure that the fuse provides appropriate protection against overcurrent without unnecessarily tripping or failing.

Regular maintenance of power fuses is essential for prolonging their lifespan and ensuring continued safety in electrical systems. Conduct periodic inspections to check for any signs of wear, damage, or corrosion. Routine checks are necessary to ensure the fuses are functioning correctly and are free from dust or oil contamination. These measures help ensure that the power fuses will operate reliably when needed, thereby preventing disruptions or potential hazards.

Replacing a circuit breaker is crucial for maintaining electrical safety and functionality. Begin by turning off the main power supply to eliminate any risk of electrical shock or further damage. Remove the faulty breaker by carefully detaching it from the panel, ensuring no residual power flows through. Install the new circuit breaker by securing it into the designated slot, confirming that all connections are tight and correct. This process not only fixes the immediate issue but also safeguards against future electrical complications. For additional guidance, you may find resources on "how to replace a circuit breaker" beneficial.

Fuses and circuit breakers have similar protective purposes but function differently in their operations. A fuse interrupts the current by melting its internal wire when excessive currents flow through, while a circuit breaker trips, creating a gap that interrupts the flow of electricity, but unlike fuses, it can be reset and reused. Fuses are known for their simplicity and cost-effectiveness, yet they must be replaced after a single use. Circuit breakers offer easy resetting without replacements and are widely favored for residential and commercial uses. Balancing the benefits and limitations of each can aid in making an informed decision for household or industrial applications.

One of the common issues with fuses is identifying when they are blown. A simple method is to check for visible signs such as discoloration or breakage in the fuse element. However, for a more accurate diagnosis, using a multimeter is recommended. This tool allows you to measure the fuse's continuity and resistance, helping to confirm whether a fuse is compromised.

Addressing overcurrent issues is essential to maintain a safe electrical system. Here are strategies to consider for this purpose:

Using these tips enhances your ability to troubleshoot and resolve common fuse-related issues efficiently.

Innovations in fuse technology are transforming the landscape of electrical safety by integrating smart features, such as IoT capabilities, which improve monitoring and control. These advancements allow for real-time data collection and analysis, enhancing the prediction and prevention of electrical faults. As these smart fuses become more prevalent, they offer automated alerts, precise diagnostics, and energy management insights, significantly boosting system reliability.

The evolution of electrical safety standards emphasizes the importance of advanced power fuses. As technology progresses and electrical systems become more complex, safety standards are updated to meet the rigorous demands of modern applications. This evolution necessitates fuses that can handle higher loads and offer enhanced protection against overcurrents and faults. Staying abreast of these standards ensures that industries can maintain compliance while leveraging the latest in power fuse technology for superior safety and performance.

2024 © Shanghai King-Tech Electronic Co., Ltd. Privacy policy